Order

Order

Online Consultation

Online Consultation 0574-63976868

0574-63976868

- Home

- About

- Product

Pneumatic series

Gas distribution series

- News

- Technology

- Recruitment

- Contact

- Download

Waiting...

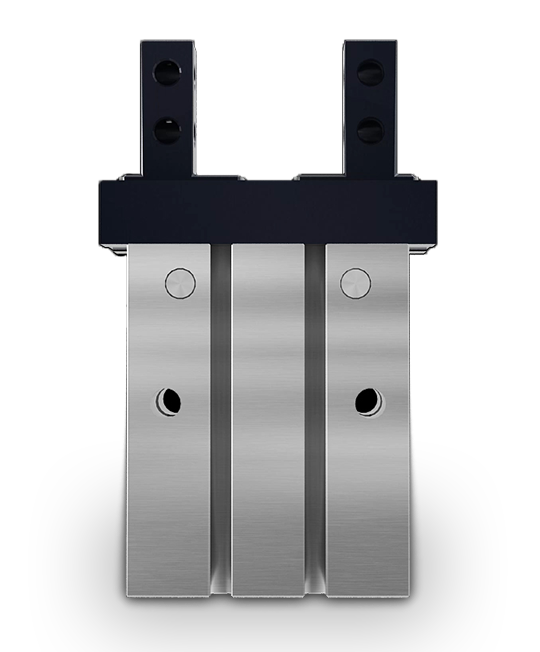

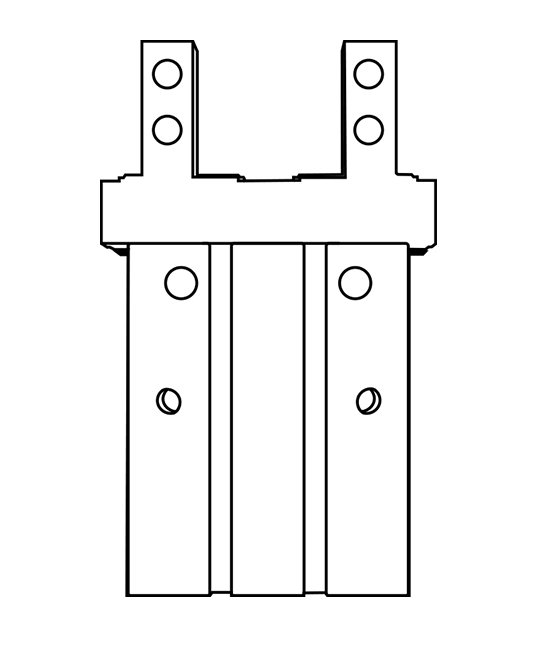

Integrated design of linear guide rail,high rigidity and high precision

View More

◇Before the pneumatic claw cylinder is fitted with pipe, the sundries and the stolen goods must be removed to prevent it from entering the cylinder.

◇Air cylinder should be filtered by 40 μm filter before use.

◇Anti-freezing measures should be taken in low temperature environment to prevent water freezing in the system.

◇In the use of the process and in the removal of long time, The air claw should be protected from surface rust.

◇Due to unexpected conditions caused by low circuit pressure, the clamping force will be reduced and the possibility of falling workpiece, in order to avoid injury to the human body or damage to equipment, must install a fall-proof device.

◇Do not use the air claw under the influence of excessive force and impact.

◇When installing and fixing the claw, do not drop, bump or damage it.

◇Please do not twist the gripper when fixing the gripper parts.

◇When installing gripper fittings, you must not clamp the guide gripper body directly, avoid damaging the guide gripper parts.

◇In order to prevent the clamping claw opening and closing speed too fast, you can install throttle speed control valve in the cylinder inlet and outlet.

◇Pinch claw in the process of work, the body can not enter the jaws of the inside, to avoid clip.

◇In the working process and the end of the stroke, the gripper and the workpiece must be left with a certain gap to avoid the gripper directly impacting the workpiece.

◇Pneumatic claw in the implementation of insertion, positioning into the action, you must ensure that the coaxial, not eccentric, so as not to touch the damage, impact loss gripper.